|

|

|||||||||

Steve Belnaviz‘s farm in Islington. Steve is the farmer who first got

Nancy interested in Jamaican chocolate.

|

|||||||||

"Chamba" (Lloyd Scott), a 70-year old farmer in Islington, harvesting cocoa

pods for our fermenting practice. Click on this link for a clip of a tour of his farm

|

|||||||||

Sastri McPherson

and Nancy practice the art of opening

the pods and beginning the fermenting process.

|

|||||||||

On February 15, 2008 we held our first organic co-op organizing

meeting for chocolate farmers in Islington, Jamaica to introduce

them to organic farming principles and to meet Dr. Dwight E.

Robinson (on the right) of the Jamaican Organic Agriculture

Movement (http://www.joamltd.org).

|

|||||||||

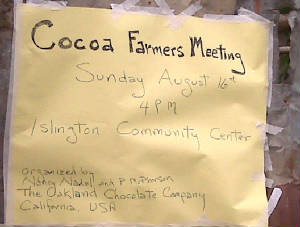

This August (2009) we had two more meetings and invited Mr. Ellis to speak to the group

about the services of the Jamaican Agricultural Society for which he is the parish President.

|

|||||||||